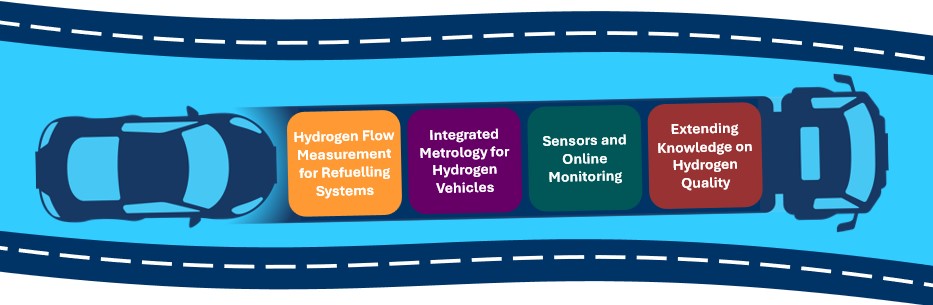

In order to realise the project, it is divided into six individual work packages (WPs). Apart from the obligatory two WPs of “Management & Coordination” and “Creating Impact”, the four central WPs to the project are; “Hydrogen Flow Measurement for Refuelling Systems”, “Integrated Metrology for Hydrogen Vehicles”, “Sensors and Online Monitoring” and “Extending Knowledge on Hydrogen Quality”. Together, these work packages will deliver new metrology infrastructure, validated procedures, and good practice guides to support the rapid deployment of hydrogen refuelling stations in Europe. They will enable accurate billing, improved safety, and reliable fuel quality control, which are critical for the operation of hydrogen refuelling stations.

This work package aims to strengthen the metrological framework for testing and verifying hydrogen refuelling stations (HRS) at very high flow rates, up to 18 kg/min for heavy-duty vehicles. The approach is based on a traceability chain using primary and secondary hydrogen standards, supported by surrogate fluids for calibrating secondary standards and testing flow meters. This will cover both 35 MPa and 70 MPa applications and demonstrate its potential for larger vehicles such as ships, trains, and aircraft. Uncertainties linked to surrogate fluid calibration will also be assessed.

This work package aims to design, build, and validate mobile verification units for hydrogen refuelling stations (HRS), traceable to SI units. These mobile verification units will combine the secondary flow standards and the validated hydrogen sampling systems in a single site visit, enabling dispenser accuracy and hydrogen quality checks. The design will support both light- and heavy-duty Hydrogen Refuelling Stations, with at least one unit suitable for both. Key objectives include compliance with OIML R139 and EN 17124, covering new SAE J2601-5 requirements, and reducing sampling and verification time by half while maintaining performance.

This task will validate the two mobile integrated Hydrogen Refuelling Station verification units. Testing will be carried out under both laboratory and real-world conditions, at hydrogen flow rates up to 18 kg/min and pressures up to 87.5 MPa. Potential interference between modules during operation will also be assessed.

This work package advance knowledge and provide technical evidence on sensors and analytical devices to optimize Hydrogen Refuelling Station Management. It focuses on leak detection sensors and analytical tools for hydrogen quality assessment, reducing operational costs and increasing stakeholder confidence. While previous projects have addressed aspects of these technologies, gaps remain—such as detecting low hydrogen concentrations and developing low-cost integrated sensors for N₂, O₂, and H₂O. Emerging technologies will be evaluated on reliable test benches, and methods will be developed to ensure representative measurements and harmonized practices. Special attention will be given to comparing laboratory and field calibration.

This task aims to identify and qualify next-generation hydrogen quality sensors and techniques (typically low TRL) capable of detecting new impurities identified in during the project. These sensors will be characterized under laboratory conditions using new protocols and evaluated for their added value in online impurity analysis compared to commercial solutions. Key performance indicators such as cost-effectiveness, impurity range, and detection limits (LODs) will be assessed.

Mapping future hydrogen fuel contaminants is critical to prevent failures that could jeopardize the sector. Rapid HRS expansion and supply chain diversification will introduce new sources and unexpected impurities, potentially impacting fuel cell vehicles. To avoid costly trial-and-error, this work package will identify these contaminants and provide reliable datasets to support the hydrogen economy rollout. It will use calibrated analysers to examine over 45 real-world samples from production, transport, and storage (e.g., gas grids, ammonia cracking, LOHC, underground storage). The focus is on contaminants beyond EN 17124 and ISO 14687 specifications, requiring advanced metrology expertise.

This work package aims to ensure that the results of the MetroHyVe3 project have a lasting impact beyond the project duration and are effectively integrated into the European hydrogen infrastructure. The focus is on the strategic dissemination of project outcomes, engaging relevant stakeholders, and supporting standardization processes. It is not only about communication but also about harmonizing measurement methods and creating a foundation for their international recognition. By building a community of industry partners, standardization bodies, and research institutions, knowledge transfer will be promoted and the acceptance of new technologies increased. Another key aspect is monitoring the long-term impact of the project results and deriving recommendations for further implementation.

This work package forms the organizational backbone of the project and ensures that all technical work packages collaborate efficiently. It includes coordinating all activities, monitoring timelines, budgets, and quality, and ensuring compliance with administrative and legal requirements. A key element is establishing clear communication structures within the consortium to guarantee smooth information exchange. Furthermore, the work package covers the preparation of regular progress and financial reports for the funding authorities and the organization of governance meetings. Another major focus is risk management to identify potential project risks early and implement measures to mitigate them.